In today’s manufacturing and supply-chain environment, product damage during handling, transportation, or storage can lead to significant losses. This is where surface protection films play a critical role.

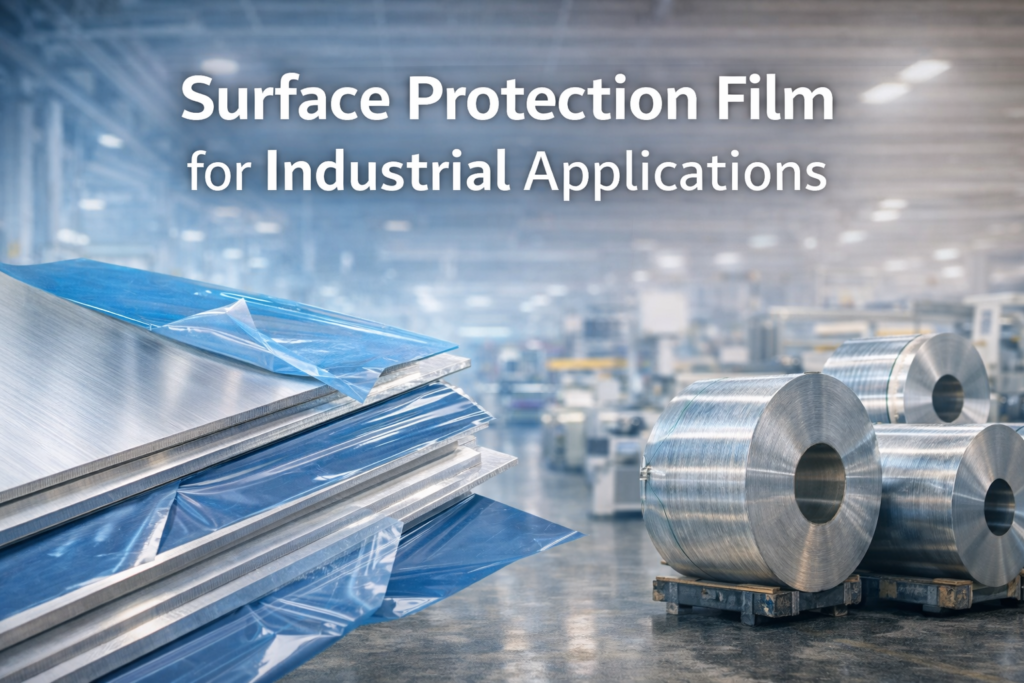

Surface protection films are specially engineered films designed to protect finished surfaces from scratches, dust, moisture, abrasion, and handling damage until the product reaches its final destination.

What Is Surface Protection Film?

A surface protection film is a temporary, peelable film applied to sensitive surfaces such as metal sheets, aluminum panels, stainless steel, glass, and coated products.

It acts as a barrier against physical and environmental damage without leaving residue after removal.

Why Surface Protection Films Are Essential for Industries

Manufacturers across industries rely on surface protection films to ensure product quality and customer satisfaction.

Key reasons industries use surface protection films:

- Prevent scratches and abrasions during processing

- Protect surfaces during transportation and storage

- Reduce rejection, rework, and warranty claims

- Maintain aesthetic finish for end customers

- Improve overall supply chain efficiency

Applications of Surface Protection Films

Surface protection films are widely used in:

- Stainless steel sheets and coils

- Aluminum sheets and ACP panels

- Pre-painted and coated metal surfaces

- Engineering and fabricated components

- Automotive and appliance parts

Each application requires a specific adhesive strength and film structure based on surface type and usage duration.

Types of Surface Protection Films

Depending on industrial needs, surface protection films are available in:

- Low-tack films for delicate or polished surfaces

- Medium-tack films for general industrial handling

- High-tack films for rough or textured surfaces

Advanced solutions like multilayer protection films offer enhanced durability and performance in demanding environments.

How Protekta Surface Protection Films Stand Out

Protekta surface protection films are designed with a deep understanding of industrial challenges. Backed by strong manufacturing expertise, Protekta delivers:

- Consistent adhesive performance

- Clean removal without residue

- Customizable thickness and adhesion

- Reliable protection for export and long-distance transport

Protekta focuses on engineered protection, not just packaging.

Choosing the Right Surface Protection Film

When selecting a surface protection film, industries should consider:

- Surface material and finish

- Exposure duration

- Environmental conditions

- Adhesive compatibility

- End-use application

Working with an experienced manufacturer ensures optimal protection without compromising surface quality.

Conclusion

Surface protection films are no longer optional they are a necessity for industries focused on quality, efficiency, and cost control.

With advanced materials and application-specific solutions, Protekta helps manufacturers protect what matters most – their products.

FAQs

Q1. Is surface protection film permanent?

No, it is a temporary film designed for easy removal after use.

Q2. Does surface protection film leave residue?

High-quality films like Protekta’s are designed for clean, residue-free removal.

Q3. Can surface protection films be customized?

Yes, thickness, adhesive strength, and film type can be customized based on application.